Mixing white masonry cement at the construction site can be straightforward when you have the appropriate tools and knowledge. To ensure this high-quality product meets your project’s demands, it’s crucial to follow the correct steps for mixing.

Another key element is having access to high-quality cement. Using bagged white masonry cement from SESCO Cement ensures consistency and performance.

Let’s dive into how to mix white masonry cement sourced from SESCO to ensure you get the most out of the product.

Follow These Steps for Mixing White Masonry Cement

Consider our step-by-step guide for mixing white masonry cement during construction jobs.

Step 1: Gather the Right Tools and Materials

Before you start, make sure you have the necessary tools and materials. Having everything ready and on hand ensures a smooth and efficient process. Here’s a quick checklist to make sure you’re all set:

Materials You’ll Need

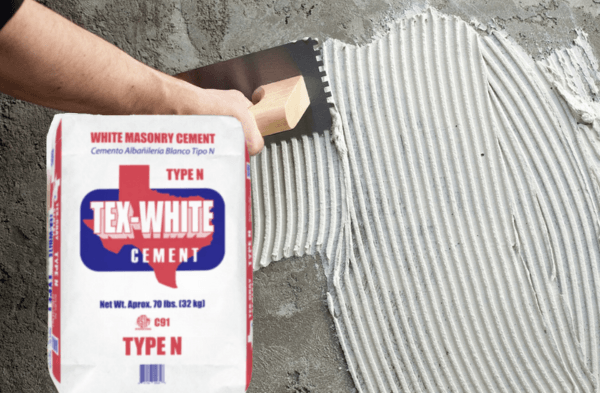

- TEX-WHITE Bagged White Masonry Cement

- Clean, fine sand (meeting ASTM C144 standards)

- Clean, potable water

- Mixing equipment (mortar mixer or mixing hoe and mortar box)

- Measuring tools (buckets or shovels for accurate proportioning)

Step 2: Measure the Proportions

The ratio of cement to sand is crucial for a strong mix. A common mix is one part white masonry cement to three parts sand. Make sure to read the instructions on the bag and measure carefully for consistency. Too much masonry sand can weaken the mix, while too little can make it difficult to work with.

Step 3: Add Water Slowly

Focus on slowly adding water to the dry mix, typically about 2.5 to 3 parts water for every 10 parts dry mix. The amount of water is crucial because you want to avoid adding too much water that could ruin the mixture. Mix thoroughly until you achieve a smooth, workable consistency.

Step 4: Mix Thoroughly

If using a cement mixer, allow it to run for 3-5 minutes to ensure a homogeneous mix. If you’re mixing by hand, keep turning the material over until the cement is fully incorporated and you achieve an even texture.

Step 5: Use Immediately

Once your white masonry cement is mixed, use it right away. Letting it sit for too long can cause it to start hardening prematurely, affecting its workability and final strength.

Tips for How to Mix White Masonry Cement for Optimal Results

Now that we’ve covered the basic steps for mixing, it’s important to keep in mind some helpful tips to achieve the best results.

- Use Clean Materials: Ensure all components, including water and sand, are clean to prevent discoloration and strength reduction.

- Protect from Weather: In hot or windy conditions, keep the mortar covered to prevent premature drying. In cold conditions, protect it from freezing.

- Consistent Mixing: Maintain consistency across all batches to ensure uniform color and strength throughout your project.

Find Support from SESCO Cement

Following this guide on how to mix white masonry cement will help you create a high-quality finished product ready to meet the demands of your job site. With proper care, our bagged white masonry cement provides the reliability and consistency needed for superior results every time.

Ready to start your next construction job? Our customer service team is standing by to receive your order for white cement in bagged quantities. We’ll help you determine the appropriate number of bags needed for the job so you can mix with confidence.