When it comes to purchasing cement for your construction supply store, the size of the bag can make a big difference for customers. Because this material is crucial in various construction tasks, stores must be able to provide these products in manageable sizes.

Fortunately, SESCO Cement offers several bagged cement options in white and gray forms. Find out more about bagged cement and how to determine the size of a cement bag to order for your store shelves.

Why Customers Buy Cement in Bags

Why should you procure cement in bags for your store? Several key factors may affect your customers’ decision to select bagged cement.

1. Convenience and Portability

One of the primary reasons customers may opt for cement in bags is the convenience it offers. Bagged cement is easier to handle, transport, and store compared to bulk cement.

For smaller job sites or one-day projects, transporting a few bags of cement is far more manageable than dealing with bulk deliveries.

2. Controlled Usage

Cement bags allow for better control over the quantity of cement used. This advantage is particularly beneficial for small to medium-sized projects where precise measurements are crucial.

With bagged cement, customers can open and use only what they need, reducing waste and ensuring the mix proportions are accurate.

3. Quality Assurance

Buying cement in bags ensures that customers receive a consistent and reliable product. Each bag is sealed to protect against moisture and contaminants, preserving the quality of the cement.

Specifically with SESCO, we include an inner polypropylene liner to keep out moisture. Also, the outer paper layer is meant to withstand a lot of physical abuse. These features are especially important for maintaining the structural integrity of construction work, where the cement must maintain a certain quality level without compromise.

Plus, we use an automatic pallet assembly line that simplifies the process of organizing and transporting bagged cement. Our reliable setup helps reduce waste and the time required to transport bags to your store.

Inside the Cement Bag Range of 70-90 Pounds

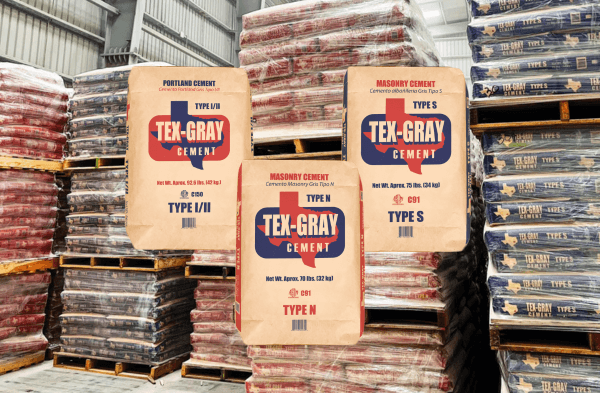

SESCO stocks six types of cement in bags (three sizes of white cement and three sizes of gray cement). The weights vary depending on the product, but all are within a manageable 70-90 lbs. Here’s why the bags are designed for this size range.

- Optimal Weight for Handling: A 70-90 lb. cement bag strikes a balance between being substantial enough for heavy-duty projects and remaining manageable for manual handling. This weight range is heavy enough to cover larger areas but light enough to be carried and mixed without requiring specialized equipment.

- Efficiency in Mixing: The bags are ideal for transporting to a job site to mix concrete. The weight provides a good ratio for combining with other materials like sand and gravel to produce concrete. The consistency and uniformity achieved with these bag sizes contribute to better quality construction work.

SESCO Has The Cement You Need

The size of a cement bag plays a crucial role in customer satisfaction and project efficiency. Opting for cement bags – particularly those in the 70-90 pound range – offers a blend of convenience, control, and quality that benefits both professional builders and DIY enthusiasts.

SESCO Cement has several varieties of white and gray cement in stock:

- White Masonry Type N – available in 70 lb. bags

- White Masonry Type S – available in 75 lb. bags

- White Portland Type I – available in 92.6 lb. bags

- Gray Masonry Type N – available in 70 lb. bags

- Gray Masonry Type S – available in 75 lb. bags

- Gray Portland Type I/II – available in 92.6 lb. bags

As you can see, the Type N cement is in the smallest size bags, the Type S cement is in the medium-sized bags, and the Portland cement is in the largest bags. Why is this the case?

Let’s start with Type N vs. S masonry cement. The difference is the compressive strength. Type N can be used in non-load-bearing applications, meaning it does not require as much material to achieve the proper ratios when mixed.

Comparatively, Type S has greater compressive strength and can be used in load-bearing applications. To achieve the correct mixture, a higher quantity of cement is required for the job. So, we package Masonry Type S cement in larger quantities.

As for Portland cement in bagged quantities, this extremely durable form of cement has even greater compressive strength than both types of masonry cement. And, because curing times can vary by a significant amount, we package as much Portland cement as possible into each bag to ensure customers can satisfy their specific project requirements.

Specifically, we package Portland cement in 92 lb. bags because it equates to approximately 1 cubic foot of cement in weight. This conversion can help with calculating how much cement is needed to complete the required job.

Contact SESCO to Order the Right Size of a Cement Bag

When we work with construction supply stores, we perform an in-depth review of the typical customers who request cement in bagged quantities. This way, we can help you order the ideal mix of bagged cement to satisfy customer demand without overstocking your shelves.

When you’re ready to discuss the size of a cement bag that will fit your customers’ needs, get in touch with our customer service team. We would be glad to discuss the requirements for your next order.